THE END OF THE BEGINNING: AUSTRALIA’S EV TRANSITION

Isuzu Comment: Grant Cooper, Chief of Strategy at Isuzu Australia Limited.

Amidst the United Nations Climate Change Conference in Glasgow, also known as COP26, Australia attends as a high income, high emitting, fossil fuels dependent economy, but nonetheless, with a semblance of a deal in hand. Given the twists, turns and synapses expended just to have Australia represented at such an important summit, it’s fair to say, this country’s path to net zero emissions by 2050 is set to be long, winding and not to mention bumpy. This particularly for a national economy that depends so heavily on the export of fossil fuels to energy intensive, developing economies around the world. Experts predict the outcomes of COP26 are unlikely to see a major breakthrough of the likes of Paris or Kyoto. But pledges on ending the use of coal, a sunset on diesel engine production and a strong commitment to net zero emissions by 2050 are all but a given.Consumer led

Given these juxtapositions, it’s a tricky setting, and especially so for those in the Australian road transport sector, where the pace of change towards decarbonisation is no longer at a jog but closer to a sprint. For many Australians, these goals are as achievable as they are timely, but as a truck OEM in Australia, this leaves my employer, Isuzu Australia Limited (IAL), in a challenging position. In the industry in which we operate, one phrase consistently rings true; ‘customer is king’, and as the push towards more sustainable, environmentally congruous transport solutions becomes an eager shove, it’s clear to see where the source of the agitation radiates from—industry and consumers.

Australian as…

Take the recently revived Ampol fuel brand as a case in point. After making a comeback in 2019 and transitioning away from the Caltex branding, Ampol recently announced it would be committing a minimum $100 million spend on future energy projects to 2025. This was a part of the Australian brand’s Future Energy and Decarbonisation Strategy and a key pillar of Ampol’s overall strategy to reach operational net zero emissions by 2040. The Ampol strategy sets out staged targets for operational emissions reductions to 2040, and importantly, pledges the development of future energy solutions for us, the consumer. These solutions take the shape of electrification, hydrogen, gas, biofuels and carbon mitigation. Ampol are reading the room too, collaborating with the likes of Tesla and Adelaide-based sustainable energy developers, Enerven. The idea is to repurpose its abundance of existing infrastructure and distribution networks, whilst juggling the concepts of energy security and orderly energy transition.Flag on the hill

As the Ampol timelines signal, orderly and responsible transition of this kind takes time and must take stock of Australia’s unique geography, demographic and road transport dependence. Ampol are backing liquid fuels to 2030 but know all too well that Australian consumers are demanding lower emissions still. From a fuel refiner, and Australia’s only refiner at that, the strategy certainly plants a bold flag on the hill.An evolving process

Isuzu too has a long history of collaborating with end users to satisfy demand, and in so doing, has evolved its own carbon neutral narrative. Since the early nineties, Isuzu Motors invested heavily in alternate fuel technology development, ultimately developing a range of compressed natural gas trucks in a bid to deliver reduced exhaust emissions, such as particulate matter.

Mass production of Isuzu’s light-duty CNG trucks began back in 1998. These were hugely popular in Japan, but as students of the local sector would know, things move a little slower in the world of Australian capital equipment.

Despite the backing of fleet giants Toll and TNT, the commercial viability of CNG as a sustainable fuel source in the Australian truck market was met with a great many challenges, most notably, a lack of refuelling infrastructure.

In 2009 Isuzu Australia rolled-out an extensive Australian evaluation of an advanced diesel electric hybrid as part of a wider low emissions initiative. Testing against existing diesel-powered units produced sound results, with a key component being the use of a low mass 346-volt, liquid-cooled lithium-ion battery pack.

Isuzu Australia took a step further in 2017, responding to customer enquiry to develop a localised electric truck concept first appearing at the Megatrans transport conference.

Again, it was a first for an Australian OEM, the market leader no less, and a bold statement.

It represented the continuing evolution of a customer-led, carbon neutral narrative and the next step on the path to a genuine ‘end use’ product.

Since the early nineties, Isuzu Motors invested heavily in alternate fuel technology development, ultimately developing a range of compressed natural gas trucks in a bid to deliver reduced exhaust emissions, such as particulate matter.

Mass production of Isuzu’s light-duty CNG trucks began back in 1998. These were hugely popular in Japan, but as students of the local sector would know, things move a little slower in the world of Australian capital equipment.

Despite the backing of fleet giants Toll and TNT, the commercial viability of CNG as a sustainable fuel source in the Australian truck market was met with a great many challenges, most notably, a lack of refuelling infrastructure.

In 2009 Isuzu Australia rolled-out an extensive Australian evaluation of an advanced diesel electric hybrid as part of a wider low emissions initiative. Testing against existing diesel-powered units produced sound results, with a key component being the use of a low mass 346-volt, liquid-cooled lithium-ion battery pack.

Isuzu Australia took a step further in 2017, responding to customer enquiry to develop a localised electric truck concept first appearing at the Megatrans transport conference.

Again, it was a first for an Australian OEM, the market leader no less, and a bold statement.

It represented the continuing evolution of a customer-led, carbon neutral narrative and the next step on the path to a genuine ‘end use’ product.

The appetite

So, what shape does this consumer demand take, and how well prepared are we as a nation to realise it? IAL’s own research report, aptly titled, The Future of Trucking (FoT), provides a unique, truck-specific insight, but the results were mixed. Fitting the pattern, consumer appetite for EV was strong with 68 per cent of the 1,000 plus respondents believing electrified trucks would play a key role in the future of the industry. Although, when queried on both their own abilities to appropriately harness an electric fleet and their views on the availability of charging infrastructure, the numbers dropped significantly.

Only 10 per cent of FoT respondents believed they were prepared for a transition, and only 20 per cent of larger, more experienced fleet respondents (the group most likely to transition) believed current charging infrastructure was suitable and sufficient for their needs.

In the world of passenger cars, things are a little different.

At the end of last year, the number of electric vehicles in Australia hit the 20,000 mark, according to Federal Chamber of Automotive Industries (VFACTS) figures, with the market showing a definite upward turn.

Although, when queried on both their own abilities to appropriately harness an electric fleet and their views on the availability of charging infrastructure, the numbers dropped significantly.

Only 10 per cent of FoT respondents believed they were prepared for a transition, and only 20 per cent of larger, more experienced fleet respondents (the group most likely to transition) believed current charging infrastructure was suitable and sufficient for their needs.

In the world of passenger cars, things are a little different.

At the end of last year, the number of electric vehicles in Australia hit the 20,000 mark, according to Federal Chamber of Automotive Industries (VFACTS) figures, with the market showing a definite upward turn.

Density blues

To realise the same uptake in the commercial trucking space, the discussion condenses down to a key issue… battery density. Namely the increase in energy density in lithium-ion batteries and the corresponding drop in cost that comes along with it. Battery energy density is the amount of energy that can be stored in the same amount of weight. As energy density increases, more energy can be extracted from a battery pack of the same weight. The good news is, those density levels have almost tripled since 2010, meaning longer ranges and reduced cost—a compelling proposition on a number of fronts. Indeed, strategic research providers, Bloomberg New Energy Finance, estimates that the average price of a complete battery pack was about $1,180 per kilowatt-hour in 2010. By 2020, it was down to around $130 per kilowatt-hour. Ultimately, this is a key factor in what makes it possible to produce a viable, end use vehicle. Perhaps the best example of this year-on-year gain can be found in the Tesla Model S, which first came to market with a 402 km range per charge. The most recent Model S with its Long Range Plus battery pack can now achieve 628 km of range per charge. That’s a 20 per cent year-on-year increase, whilst retaining the same battery pack design. Let’s not forget that this is an evolving process and advancements need to be made alongside other improvements such as mass reduction (shedding weight), aerodynamics, battery management system optimisations, drive unit efficiencies, energy retention through regenerative braking and the continued investment in another key element, that being fast charging. This phase has been labelled the ‘end of the beginning’; the shift out of ‘early adopter’ and into mainstream.The Isuzu approach

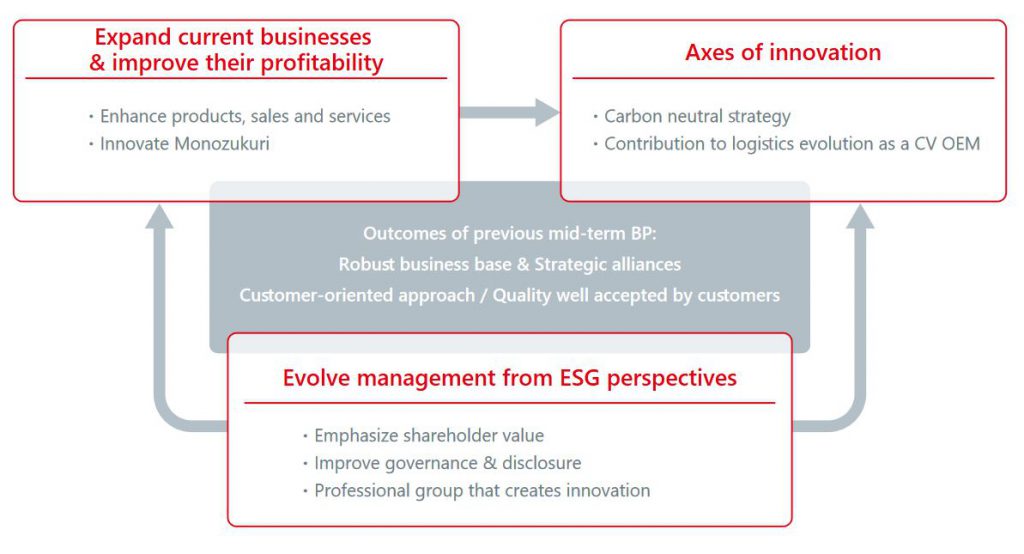

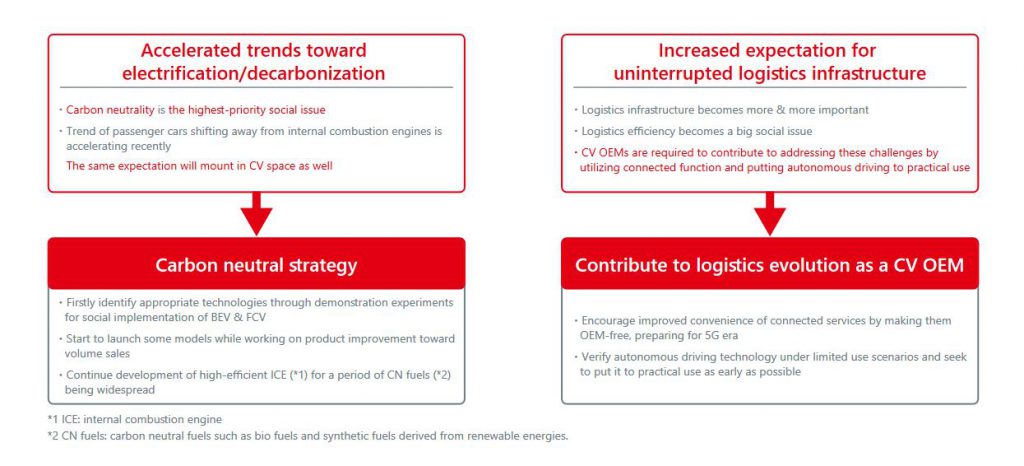

It’s within this context that we can announce Isuzu’s plans for the future of EV, not only internationally, but at home in Australia too. Outlined within Isuzu Motors’ (Japan) latest Mid-Term Business Plan, the key focuses of this strategy include Isuzu’s overarching proposal and timelines for transition, the brand’s carbon neutral strategy and vision to 2050, and what this strategy means from a product standpoint globally and here in Australia. Two key objectives underpin the strategy, namely the improvement of logistics efficiency and the brand’s move toward carbon neutrality by 2050.

From a high level, this approach is about advancing business practices that promote decarbonisation.

Isuzu is looking at this through the lens of an entire product lifecycle, with four key areas of activity centring around climate change, resource recycling, environmental risk management and biodiversity conservation.

What’s more, Isuzu is committing to an aspiration of zero greenhouse gas emissions or GHG by 2050. This will be achieved in part by reducing energy use and actively introducing clean, renewable energy technologies.

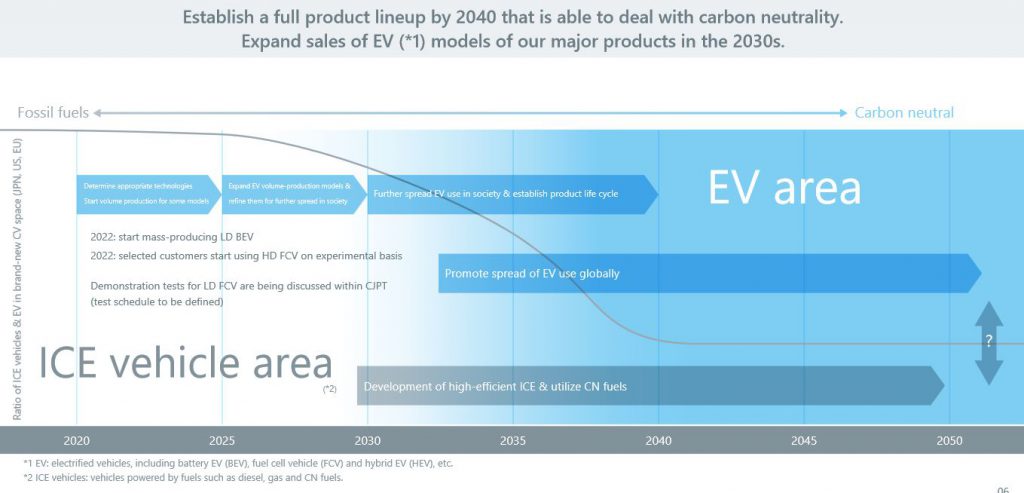

In another safe and staged approach, Isuzu is aiming to establish a full product line-up that is fully carbon neutral by the year 2040. At the same time, it will accelerate EV sales of major product lines in the decade prior.

Based on this timeline, we’re currently in the advanced testing and development phase. Indeed, Isuzu sees volume production for some EV model lines to appear in priority markets from 2022.

Two key objectives underpin the strategy, namely the improvement of logistics efficiency and the brand’s move toward carbon neutrality by 2050.

From a high level, this approach is about advancing business practices that promote decarbonisation.

Isuzu is looking at this through the lens of an entire product lifecycle, with four key areas of activity centring around climate change, resource recycling, environmental risk management and biodiversity conservation.

What’s more, Isuzu is committing to an aspiration of zero greenhouse gas emissions or GHG by 2050. This will be achieved in part by reducing energy use and actively introducing clean, renewable energy technologies.

In another safe and staged approach, Isuzu is aiming to establish a full product line-up that is fully carbon neutral by the year 2040. At the same time, it will accelerate EV sales of major product lines in the decade prior.

Based on this timeline, we’re currently in the advanced testing and development phase. Indeed, Isuzu sees volume production for some EV model lines to appear in priority markets from 2022.

The concept

In terms of an OEM produced product, we have reference in the form of the ELF Electric Walkthrough concept truck, first displayed at the 46th Tokyo Motor Show in 2019. In a recent innovation boon of Australia, this concept vehicle left Japanese shores and landed at IAL headquarters in Melbourne. This was a first for Isuzu globally and speaks to the extremely high regard Australia is held in as a frontline, early adopter market. Since 2019 energy density levels have shifted considerably. At the time of the ELF’s release, standard energy density benchmarks sat at approximately 180 Wh/kg, whilst today, industry benchmarks sit at approx. 260Wh/kg—an approximate 20 per cent year on year improvement.

This improvement is also reflected in cost, with an 18 per cent year-on-year drop in the cost of battery per kilowatt hours.

Upon release, the ELF’s electric motor produced 150 kilowatts, or around 201 horsepower, specifically developed for short-haul, ultra-urban applications and arguably, rightly so.

Given IAL’s booming light-duty sales volume trends, the ELF Walkthrough concept is well geared to serve as a local vision of what a fully electric, urban pickup and delivery truck could look like on our roads.

In the next few days, Prime Minister Scott Morrison lands in Scotland armed with new policy amid changing local and international sentiment on the environment.

The outcome of this and the effect on some Australian industries remains to be seen.

Needless to say, transition is already well underway.

For the broader automotive industry at least, this continues to be a consumer and industry led revolution in spite of the many hurdles that continue to present themselves.

Indeed, it’s this collective and steadfast focus on innovation, be that the optimisation of existing and emerging technologies, or the ambition of a carbon neutral future, that will effect tangible change.

It’s certainly an exciting time to be in this industry and the future looks bright.

Since 2019 energy density levels have shifted considerably. At the time of the ELF’s release, standard energy density benchmarks sat at approximately 180 Wh/kg, whilst today, industry benchmarks sit at approx. 260Wh/kg—an approximate 20 per cent year on year improvement.

This improvement is also reflected in cost, with an 18 per cent year-on-year drop in the cost of battery per kilowatt hours.

Upon release, the ELF’s electric motor produced 150 kilowatts, or around 201 horsepower, specifically developed for short-haul, ultra-urban applications and arguably, rightly so.

Given IAL’s booming light-duty sales volume trends, the ELF Walkthrough concept is well geared to serve as a local vision of what a fully electric, urban pickup and delivery truck could look like on our roads.

In the next few days, Prime Minister Scott Morrison lands in Scotland armed with new policy amid changing local and international sentiment on the environment.

The outcome of this and the effect on some Australian industries remains to be seen.

Needless to say, transition is already well underway.

For the broader automotive industry at least, this continues to be a consumer and industry led revolution in spite of the many hurdles that continue to present themselves.

Indeed, it’s this collective and steadfast focus on innovation, be that the optimisation of existing and emerging technologies, or the ambition of a carbon neutral future, that will effect tangible change.

It’s certainly an exciting time to be in this industry and the future looks bright.

Playtime’s over, get $3,500* to spend on extras.

If you’re ready to get serious about tackling bigger jobs, grab yourself an NLR 45-150 AMT SWB Traypack from the Ready-to-Work range for $62,990 drive away*. And to prove we aren’t playing, buy any NLR Traypack before June 30 and you’ll get $3,500* to spend on genuine accessories or an Essentials service agreement.

Learn more