Tinker, tailor, teacher: Isuzu Power Solutions in the classroom with TAFE SA

After two decades of skilled labour shortage, workshops across the country are still seeking up to 40,000 technicians to join the force—making for opportunities aplenty for talented new mechanics and technicians to get a foot in the door of the automotive industry in Australia.

Educational institutions such as TAFE South Australia have an exciting range of courses for apprentices and new students to gear up for a career in the industry.

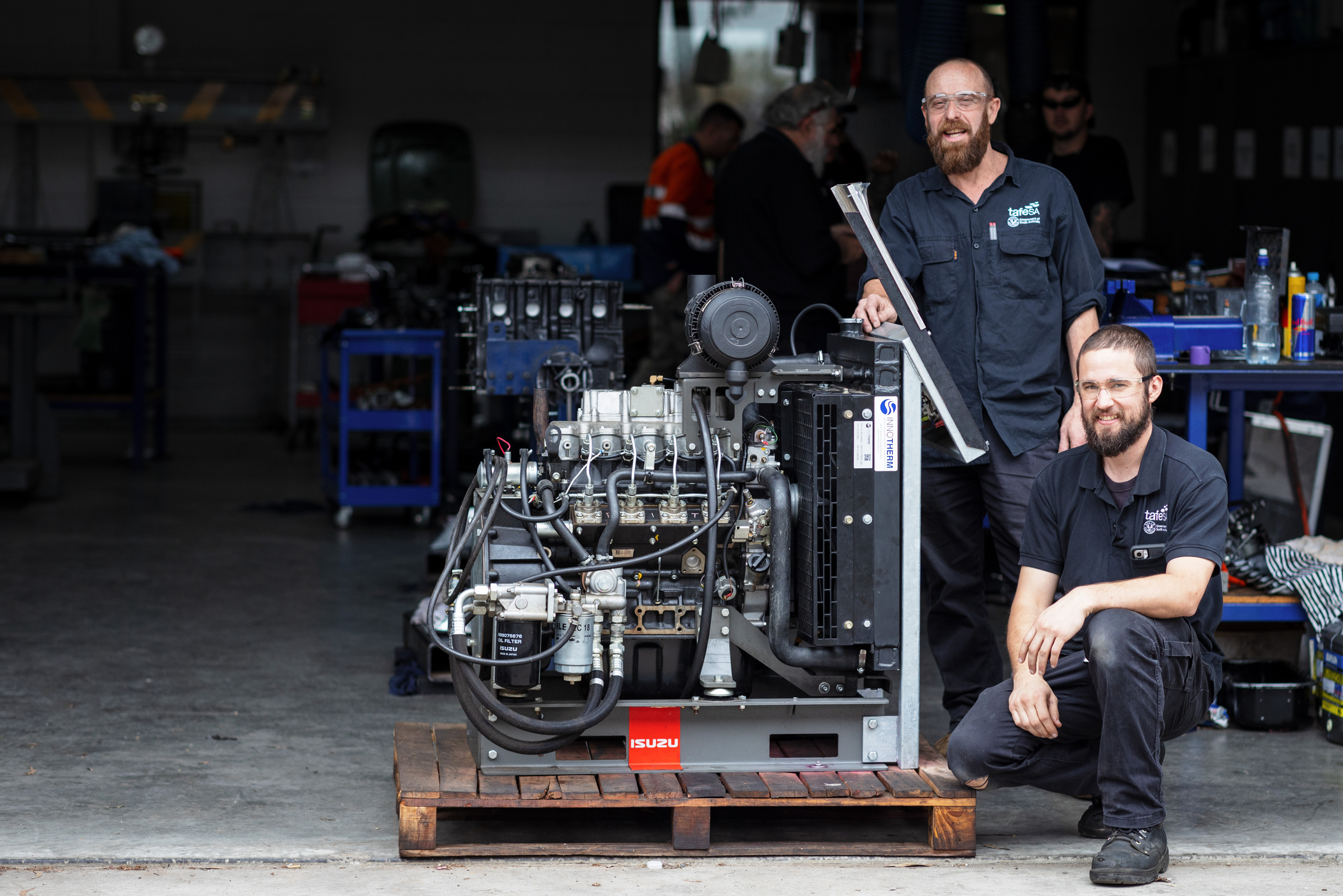

Here, the likes of experienced automotive technicians such as Paul Garth and David Askew can be found lecturing and preparing students with training on equipment such as Isuzu Power Solutions (IPS) units and engines, which they can expect to be handling regularly in real workshop situations.

TAFE SA recently acquired six IPS 4LE1N industrial power units from their local supplier Engine Pump and Power in Adelaide for students to tinker with, strip-down and repair as part of their learning program.

“We just purchased six Isuzu engines for the workshop, which is what we were after for teaching those fundamentals,” David said.

“They're simple, mechanical engines, without too much electrical or fuss which is just perfect for us.”

Paul Garth (front) and Dave Askew (standing) from TAFE SA

Start your engines

Paul and David both lecture in heavy vehicle programs but many of the other automotive courses will cross their paths, particularly when it comes to any hands-on application.

“We cover three streams as part of the heavy vehicle section, so we cover off a lot of mobile plant equipment, road transport and agriculture machines,” explained Paul.

“We also cover anything from diesel fuel systems, engine management and engine rebuilding.

“We try to provide anything and everything a student needs to succeed in the industry… from our point of view, it’s a really rewarding job.”

The training provided in these courses prepares a student to tackle a wide range of issues from engine diagnosis through to life skills that are applicable almost anywhere.

Curiosity, problem solving, and perseverance are taught together with engine theory as a successful technician needs those attributes and many more.

Time and again

However, nothing beats the feeling of having heavy metal under hand.

In the classroom, one of the most important factors for the equipment being used by students in the heavy vehicle courses is replicability—anything taught to one group must be able to be replicated with another class.

Equipment also needs to stand up to the extraordinary burden of being taken apart time and again by a multitude of different people and levels of experience.

This is where David and Paul use the six 4LE1N industrial power units. It’s also where Isuzu’s reputation for reliability, in somewhat unusual conditions, is put to the test.

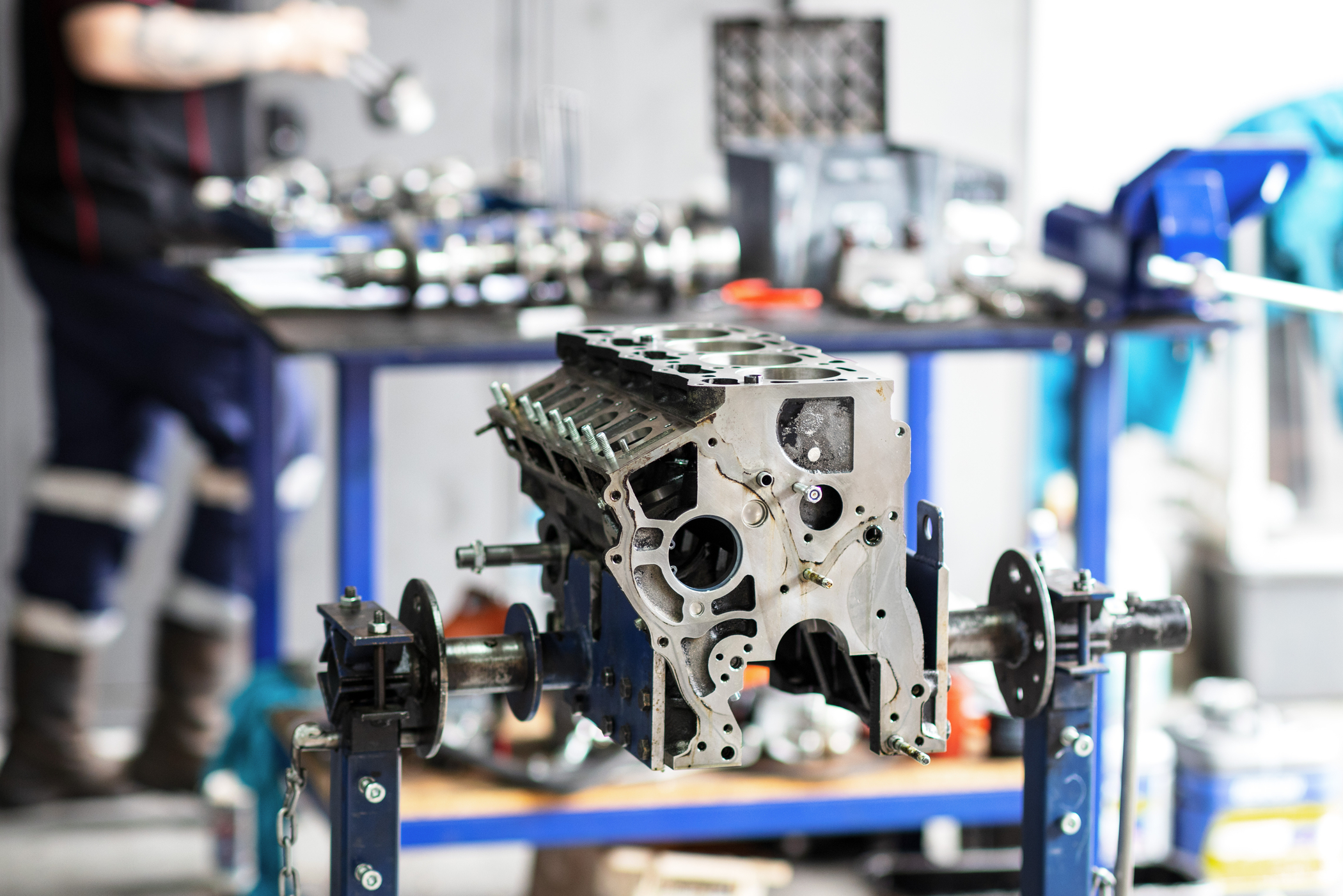

“One of our courses is called ‘diagnose and repair’ and its focus is how an engine works and how to strip it down.

“The students will strip it down in its entirety, so get the crank shafts out, conrods, pistons, everything.

“They’ll follow the Isuzu manual for all of that and then they will assess the engine,” Paul explained.

“I think these engines have probably been stripped down and put back together dozens of times already and they’re still reasonably new, if that gives an idea of how many times it’s going to happen… that’s the reason why we choose to work on Isuzu engines.”

Design principles

IPS engines are built tough and sturdy for a hard life on the road or supporting operations as stand-alone power units. The six 4LE1N units at TAFE SA are receiving an equally gruelling workout from the students.

As with all IPS product, the 4LE1N unit features a genuine Isuzu engine manufactured in Japan, specified for the harsh Australian climate. This model comes with a heavy-duty aluminium cooling system rated to 45°C (50°C on premium models), features Australian-designed and sourced engine mounts and skids, and a heavy-duty bar and plate along with premium quality air cleaners.

The four-cylinder 4LE1N unit is rated at 48 hp (41 hp continuous) with a 2.2 litre displacement and maximum power and torque output of 35.9 kW @ 2,600 rpm and 140 Nm @ 1,800 rpm. It’s designed for low fuel consumption, low maintenance and low noise, making for an efficient tool that is quiet enough to run while Paul and David are teaching a class.

TAFE SA have engineered their own frame for the power units for installation in the class workshop, enabling easy access and disassembly. This complements a custom analogue control panel on each unit to monitor system vitals fitted by Greg Williams and the team at Engine Pump and Power.

Real world application

With the six new IPS units joining the stocks of teaching aids, it’s a great illustration of how real-world product can be utilised as a tool to sharpen the abilities of the nation’s next generation of technicians.

"It’s a funny dichotomy,” David mused. “You want something that's going to provide a challenge but that’s capable of taking a beating, because we will put them through years of wear.

“In that respect, it's even more realistic of the workplace…. you're not going to be pulling apart a brand-new engine on any regular job, it's going to be coming into the workshop for a reason.

“We need an engine that’s easy to assess, easy to fix and hard to kill.”

With one in four trucks on Australian roads sporting an Isuzu badge, it’s more than likely any workshop technician will be encountering an Isuzu power product or standalone unit such as the 4LE1N regularly.

And if those early days of learning do somehow slip away—as David and Paul can attest —almost everything you need to know about an Isuzu engine can be found again in the manual.

Lead the charge with Australia’s favourite truck.

2025 heralds Isuzu Trucks’ 36th year as market leader.* Number one in more than just sales, though, Isuzu Trucks has an unparalleled dealer support network, customer care program, truck range, and legendary reliability. To get behind the wheel of a winner, get into your nearest Isuzu Trucks Dealer now or visit isuzu.com.au

Learn More