Isuzu Australia Limited (IAL) has demonstrated the company’s future product development methodology—a key phase of the brand’s latest model launch—during a recent media visit to Isuzu Motors Limited’s (IML) manufacturing plant in Fujisawa, Japan.

Some of Australia’s foremost transport journalists had the opportunity to witness Isuzu’s new Modular Architecture and Component Standard, otherwise known as I-MACS, in the flesh during a rare, behind the scenes tour and product presentation.

A FRESH APPROACH

Developed by IML in Japan, I-MACS is a revolutionary approach that allows the combination of various components, parts, and devices to be applied in anticipation of future advancement in technologies and the expansion of vehicle types into the future.

Head of Product at IAL, Matt Sakhaie

Head of Product at IAL, Matt Sakhaie, delved deeper into the process, which is poised to form a key part of Isuzu’s future product development methodology, both globally and at home in Australia.

“There are a range of factors impacting Australian customers in the near future. We see these radiating from issues such as changes in regulation and legislation, technological advancements, as well as a level of post-pandemic uncertainty across a variety of industries,” Mr Sakhaie said.

“Isuzu Australia has a strong reputation for reliability and dependability, which is what I-MACS will continue to deliver for our customers so that they are well-supported as they tackle these challenges.

“In the simplest terms, the I-MACS approach is a balance between what customers have been asking for up until now and what will be demanded in the new era of transport,” he said.

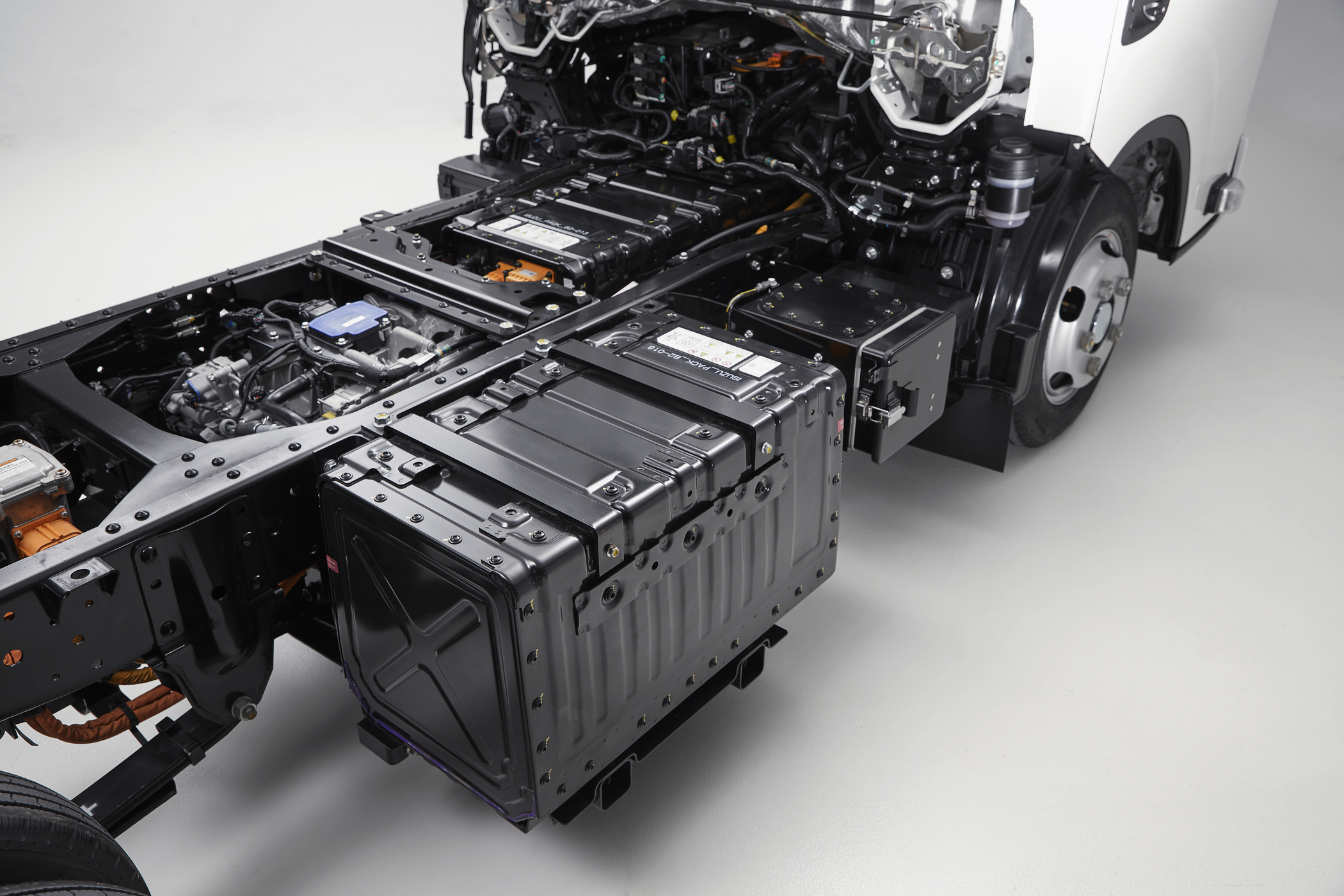

I-MACS allows for the interchange of key componentry

EFFICIENCIES GAINED

By better understanding the link between vehicle components and the notion of interchanging or relocating them, I-MACS makes it possible to adapt to the future while remaining compatible with legacy models.

I-MACS breaks with the convention of developing model-specific parts, which can lead to huge variations in component development as vehicle models evolve.

By standardising and reducing the number of model-specific parts and components, I-MACS presents the ability to interchange key componentry such as…

- ICE power plants

- Transmission types

- Fuel cell stacks

- Hydrogen tanks

- Batteries and charging equipment (EVision Cycle Concept)

- Fuel tanks

- Axles

- Advanced safety devices

As Mr Sakhaie explained, an additional benefit of the approach is how it is helping to create efficiencies across IML’s global operations; namely, on its vast production lines.

“Instead of setting up new main production lines for the new-generation models, Isuzu have re-structured the same main assembly lines for both new and prior generations.

“Backed by I-MACS, the aim is to reduce man-hours and further capital investment,” he said.

THE TEST OF TIME

As I-MACS vehicles expand overseas and into developed and emerging countries, Isuzu’s expects to see more data-driven results.

“We are at the starting point of a longer journey. Backed by the capabilities of I-MACS, we believe we’re extremely well positioned to respond to whatever conditions the future may hold and support our customers with ongoing reliability and the quality they’ve come to know and trust,” Mr Sakhaie concluded.

The all-new Isuzu truck range is about to arrive.

Register your interest and we'll keep you in the loop with the latest updates.

Learn More